Copper is actually a better conductor of heat than aluminum. The problem is a copper radiator is not ALL copper. The tubes and fin are copper however they are bonded together with lead, which has horrible heat transfer capabilities. The end tanks are brass and the side channels are steel. The trick to better cooling is wider tubes and shorter fin. This increases the “tube to fin” contact area, which determines the radiator efficiency.

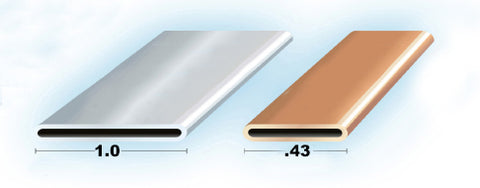

A typical 4 row copper radiator uses 7/16" tubes while the aluminum radiators use two rows 1" tubes.

Then the copper radiator uses 1/2 tall fin while the aluminum radiator uses 3/8" fin. The shorter fin increases the number of tube layers in a given stack up. For example a 18.5" tall radiator has 30 layers for the copper unit versus 40 layers for the aluminum. So you have more layers per stack up and more surface area in each layer.

The aluminum radiator is 100% aluminum furnace brazed without any insulating solder. That is why aluminum radiators work better than copper ones. If you could build a copper radiator the exact same way we make the aluminum ones, it would work better than the aluminum. It would also weigh about 90 pounds.